Jacket Lift System (JLS) Beam

Jacket Lift System (JLS) Beam

CLIENT: Allseas

PROJECT: Allseas

CONSTRUCTION: Cimolai S.p.A.

SEA TRANSPORT, GRILLAGE AND SEA FASTENING: Allseas

GROUND TRANSPORT AND LOADOUT: Cimolai S.p.A.

Cimolai has built the two longest beams in the world, each weighing 6700 t

and 170 m in length, including a 26 m hinged tail. Cimolai also designed

the grillage and sea fastening for their transport by sea from Monfalcone to

Rotterdam. The two beams are the main beams of the Jacket Lift System

(JLS), an innovative system for installing and/or removing jackets from

offshore platforms. The JLS is able to move up to 20000 t of steel in a

single lift and will be installed on the stern of the construction ship

Pioneering Spirt by Allseas, which is more than 380 m long and 124 m wide.

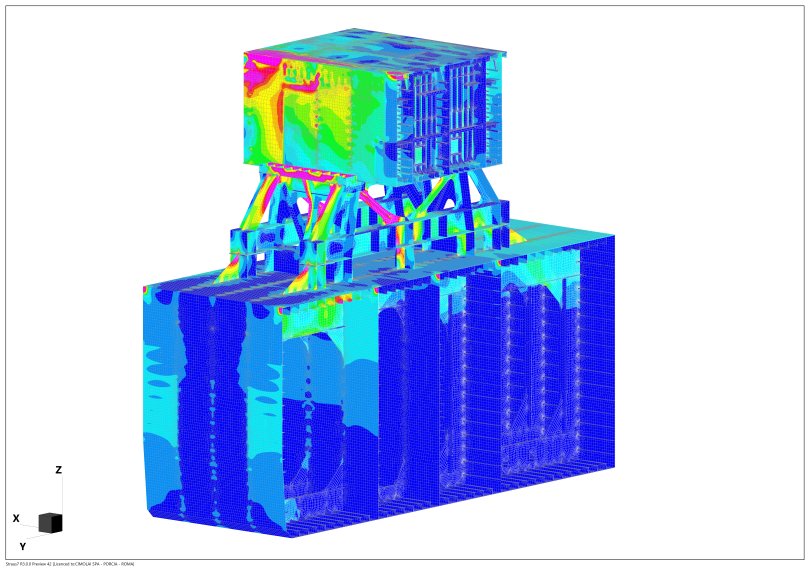

Cimolai used the Straus7 finite element system to create the FEM models of

the grillage combined with partial models of the JLS beam and the gigantic

barge Iron Lady, and to perform linear and non-linear analysis for the

verification of stress and deformation due to various load combinations in

the load-out as well as the navigation phase of the barge for waves up to 7

m in height. Local models with refined mesh were used for structural

verification of strength and stability and for fatigue verification of the

welds at the major connections between the barge and the JLS beam itself.

Text, photo and images of finite element model, courtesy of Cimolai S.p.A.

|

Cimolai has built the two longest beams in the world, each weighing 6700 t and 170 m in length, including a 26 m hinged tail. Cimolai also designed the grillage and sea fastening for their transport by sea from Monfalcone to Rotterdam. The two beams are the main beams of the Jacket Lift System (JLS), an innovative system for installing and/or removing jackets from offshore platforms. The JLS is able to move up to 20000 t of steel in a single lift and will be installed on the stern of the construction ship Pioneering Spirt by Allseas, which is more than 380 m long and 124 m wide. Cimolai used the Straus7 finite element system to create the FEM models of the grillage combined with partial models of the JLS beam and the gigantic barge Iron Lady, and to perform linear and non-linear analysis for the verification of stress and deformation due to various load combinations in the load-out as well as the navigation phase of the barge for waves up to 7 m in height. Local models with refined mesh were used for structural verification of strength and stability and for fatigue verification of the welds at the major connections between the barge and the JLS beam itself. Text, photo and images of finite element model, courtesy of Cimolai S.p.A. |

For further information about Straus7 please contact us by e-mail: straus7@hsh.info